The science behind optical measurement: fundamentals explained

Wiki Article

The Role of Optical Measurement Systems beforehand Assessment Strategies

Optical measurement systems have actually transformed metrology, bringing a level of precision that was once unbelievable. As you check out even more, you'll uncover exactly how these systems are forming the future of measurement and top quality control.The Advancement of Width: A Historic Perspective

As you discover the background of width, you'll discover that its evolution mirrors mankind's quest for accuracy and standardization. From old civilizations using body components as units of measurement to the growth of standardized weights and procedures, each action reveals our need for precision. The Egyptians constructed the pyramids using accurate dimensions, while the Romans progressed design with their advanced measuring tools.Throughout the Renaissance, clinical developments moved the focus toward a lot more empirical methods, paving the way for modern-day metrology. The intro of the metric system in the late 18th century marked a considerable turning point, developing universal requirements. Throughout the 20th century, technical improvements further transformed assessment, enabling very accurate dimensions in various fields.

Today, width continues to evolve, incorporating digital innovation and automation. This history highlights not simply the significance of measurement yet also our relentless search of improving accuracy and uniformity in our progressively complex world.

Principles of Optical Dimension Systems

Comprehending the concepts behind optical measurement systems is essential for accurate cause width. You'll want to take into account basic optical principles, dimension accuracy factors, and efficient system calibration strategies. Each of these components plays a vital function in guaranteeing your measurements are specific and trustworthy.Basic Optical Concepts

While exploring optical dimension systems, you'll run into essential optical concepts that create the backbone of accurate information acquisition. Light behaves in predictable methods, and understanding these habits-- like reflection, refraction, and diffraction-- is crucial for reliable dimensions. You'll use lenses and mirrors to adjust light and concentrate it onto your target, making certain precision in your readings. Furthermore, the wave nature of light permits interference patterns, which can enhance dimension resolution. Polarization can additionally play a key function in distinguishing signal from sound, improving the clarity of your results. By mastering these principles, you'll be equipped to leverage optical modern technologies effectively, paving the means for advancements in assessment and guaranteeing your dimensions are both repeatable and trustworthy.Measurement Accuracy Aspects

To achieve high measurement precision in optical systems, a number of variables come right into play, affecting the integrity of your outcomes. First, the quality of the optical parts matters considerably. High-grade lenses and detectors reduce aberrations and noise, guaranteeing your dimensions are precise. Second, environmental conditions like temperature and moisture can influence dimensions, so preserving a stable environment is vital. Third, the positioning of the optical system is critical; even minor imbalances can lead to significant mistakes. Finally, the wavelength of light utilized effects the resolution and accuracy of your measurements. By resolving these elements, you can boost the overall performance of your optical dimension systems, resulting in even more accurate and reliable cause your metrology applications.System Calibration Techniques

Attaining high dimension precision is just part of the formula; appropriate system calibration techniques are equally important in optical dimension systems. To ensure your system delivers trustworthy outcomes, you must routinely calibrate it using standard referral materials. Begin by changing the optical parts, like lenses and mirrors, to minimize methodical mistakes. Next, use recognized measurements to confirm the system's output and make essential adjustments. It's also crucial to account for ecological factors-- temperature level and humidity can impact dimensions. Carry out a regular calibration timetable to maintain uniformity with time. Ultimately, document all calibration treatments and outcomes; this will certainly assist you track performance and resolve any kind of drift in accuracy. With these techniques, you'll boost the integrity of your optical dimension system.

Secret Technologies Behind Optical Dimension

Optical dimension systems rely upon several essential modern technologies that improve precision and performance in assessment. One essential technology is interferometry, which utilizes the interference of light waves to measure tiny displacements and surface abnormalities with severe accuracy. You'll likewise locate laser scanning systems, which capture detailed 3D information of objects rapidly, making them important for dimensional analysis.In Addition, CCD and CMOS sensing units play a significant function in transforming light right into electric signals, enabling high-resolution imaging and accurate measurements. Advanced algorithms for photo processing additionally enhance dimension precision by analyzing information in actual time, filtering system out noise and boosting functions.

Lastly, fiber optics supply adaptability and the capacity to gauge in difficult settings while keeping signal honesty. By leveraging these innovations, you can accomplish remarkable lead to your assessment jobs, ensuring that your dimensions are both exact and dependable.

Applications of Optical Dimension in Sector

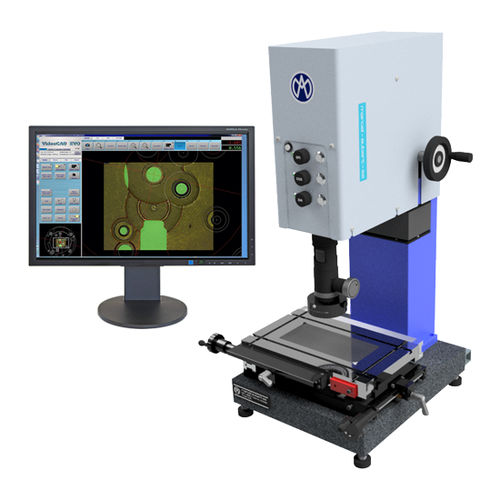

As industries significantly demand accuracy and performance, the applications of optical dimension systems have ended up being crucial across numerous sectors. In manufacturing, these systems help you monitor dimensions and resistances in real-time, ensuring quality assurance without time-consuming hands-on optical measurement system checks. In the vehicle industry, optical dimensions aid in aligning parts with accuracy, improving security and efficiency.In electronic devices, you're making use of optical approaches to inspect min attributes on circuit boards, discovering problems that could lead to failings. The aerospace sector take advantage of non-destructive screening methods, allowing you to evaluate materials and elements without compromising their stability.

Optical measurement additionally plays an important function in textiles, ensuring material dimensions fulfill exact specifications. optical measurement systems. With their capability to provide high-resolution information swiftly, these systems encourage you to make enlightened choices, simplify processes, and ultimately drive development across your market

Enhancing Precision and Performance in Measurements

When you think of improving precision in measurements, accuracy in your dimension methods is essential. By simplifying these processes, you can attain quicker results without compromising top quality. Let's explore exactly how taking on innovative optical dimension systems can boost both accuracy and efficiency in your work.Accuracy in Dimension Methods

Accuracy in dimension methods is important for attaining trustworthy cause assessment, especially considering that tiny discrepancies can lead to significant errors. By using innovative optical measurement systems, you can enhance the precision of your measurements. These systems provide high-resolution data that aid you identify also the tiniest variations in measurements. You minimize uncertainties and improve repeatability in your procedures when you take on these technologies. In enhancement, precise measurements allow you to keep top quality control, ensuring that products meet rigorous specs. This not just boosts your trustworthiness however also boosts client contentment. Buying accuracy measurement devices eventually results in enhanced efficiency, lowered waste, and optimized production cycles. Accepting these techniques will certainly transform your approach to assessment, generating remarkable outcomes.Streamlining Measurement Procedures

To improve precision and efficiency in measurements, streamlining your measurement processes is necessary. Start by taking on optical dimension systems that supply real-time data, decreasing the moment invested on hands-on recording. These systems usually integrate seamlessly with existing software program, enabling you to automate data collection and evaluation.Following, standardize your dimension procedures. By executing constant procedures, you reduce variability and improve repeatability. Don't fail to remember to consistently calibrate your tools to ensure its accuracy.

The Impact of Optical Measurement on R & D

As scientists endeavor to press the borders of innovation, optical measurement systems have actually come to be crucial devices in the development procedure. These systems supply you with precise, real-time data that enhances your capability to assess complicated products and frameworks. In various areas, from biotechnology to aerospace, you depend on optical dimensions to maximize layouts and enhance item performance.

With high-resolution imaging and non-contact methods, you can lessen sample disturbance, permitting even more precise results. This capability to record minute details increases your R&D cycle, allowing you iterate designs quickly and successfully. In addition, optical measurement fosters partnership across disciplines, as the data generated is often conveniently interpretable and shareable.

Eventually, integrating optical measurement systems right into your study not only boosts performance yet likewise deepens your understanding of the sensations you research. By leveraging these sophisticated strategies, you're much better furnished to innovate and stay ahead in a competitive landscape.

Future Trends in Optical Measurement Systems

With the quick development of technology, you're likely to see substantial changes in optical dimension systems that will certainly redefine their application across different markets. You'll notice an approach increased automation and combination of expert system, permitting for real-time data evaluation and boosted accuracy. Miniaturization is an additional pattern; compact gadgets will make it possible for measurements in tighter spaces, making them ideal for fields like aerospace and biomedical applications.Anticipate to see systems that can operate in challenging settings, giving reliable dimensions in extreme problems. As these technologies merge, you'll find that optical dimension systems not just improve accuracy however likewise streamline process, inevitably driving technology and effectiveness in your tasks.

Regularly Asked Inquiries

Exactly How Do Optical Dimension Equipments Compare to Traditional Measurement Techniques?

Optical measurement systems offer higher accuracy and faster results contrasted to typical methods. You'll find they catch more information factors precisely, lowering human error and enhancing reliability, making them a preferred choice in numerous applications.What Industries Benefit Many From Optical Dimension Solutions?

You'll discover sectors such as aerospace, auto, and electronic devices profit most from optical measurement systems. These industries rely upon specific measurements to guarantee quality and efficiency, boosting effectiveness and decreasing costs through innovative modern technology.

Are Optical Dimension Equipments Expensive to Execute?

Optical measurement systems can be expensive to implement, but their accuracy and performance typically warrant the price. Buying such technology can lead to significant lasting cost savings and renovations in high quality across different applications.What Abilities Are Called For to Operate Optical Dimension Systems?

To operate optical dimension systems, you'll need solid analytical skills, attention to information, and efficiency in software devices. Familiarity with optics and an understanding of measurement principles will likewise improve your efficiency and performance.Just How Do Environmental Elements Impact Optical Measurements?

Environmental factors like air, temperature level, and moisture quality can misshape optical dimensions. You'll notice variants in precision due to light disturbance or refraction. optical measurement system. Preserving stable problems is crucial for reliable and precise optical measurement results

Final thought

In summary, optical dimension systems are changing metrology by providing unparalleled accuracy and performance. As you check out future trends, you'll see just how the assimilation of AI and automation will certainly continue to boost dimension techniques, driving technology and improving quality control.Achieving high dimension precision is only component of the formula; appropriate system calibration techniques are equally vital in optical measurement systems.When you assume about boosting precision in measurements, accuracy in your measurement methods is essential. By using advanced optical dimension systems, you can improve the accuracy of your dimensions.To boost precision and effectiveness in dimensions, streamlining your dimension procedures is crucial. Exactly How Do Optical Dimension Equipments Compare to Conventional Dimension Techniques?

Report this wiki page